Fostering innovation

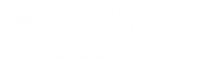

Innovation leads to new processes and new products that meet needs and address challenges such as those related to health and the environment. At the same time, innovation stimulates productivity, creates jobs and helps improve the community’s quality of life. The teams develop new and original primary ingredients corresponding to market trends, and create original and innovative formulas with special attention to sensory characteristics and origin of ingredients. Primary ingredients cannot always be used in their natural and original form.

They must also meet qualitative criteria and be workable in formulas. Our team transforms these ingredients through solubilization, encapsulation, de-resination and deodorization for use in our products. We work closely with leading luxury cosmetics brands, producing natural extracts according to their strict specifications.

These collaborations frequently result in the transfer of processes. Our expertise lies in the creation, formulation and manufacture of cosmetic products. Our cosmetics are created according to detailed specifications and to clients’ demands regarding appearance, organoleptic properties, effectiveness, conservation and packaging, and are tailored to future users.

Our passion for creating cosmetics goes into each and every product, all inspired by the bounty of French Polynesia and always responsive to consumers’ needs and desires.

Among the various initiatives we developed over the course of this year was the program to screen plants for potential use, which was used to analyze approximately 10 species. This selection was made according to three criteria: sourcing, chemical/biological profile and commercial profile.

Practicing responsible management

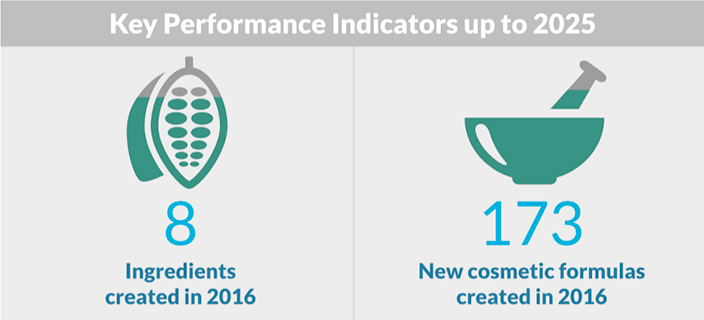

By adhering to ethical purchasing practices that are in line with the company’s overall strategy, we demonstrate our commitment to raising awareness among our customers through our values. To contribute to the development of the local economy, we have set the objective of sourcing 90% of our purchases locally. In 2016, the share of purchases made in French Polynesia by LCPS was 78% (excluding copra oil), and the share of purchases made in France by PSi was 90%.

We consider the impact of our purchasing on our organization, our environment and our suppliers while keeping an eye on overall costs. As subcontracting non-core operations is a common business practice, LCPS has chosen to partner with Ateliers Pour la Réinsertion Professionnelle (APRP, which translates as “workshops for vocational reintegration”) for the packaging of certain products in plastic, and to work with an independent contractor based in Papara to crush tamanu nuts.

At our site in the South of France, we strive to foster an inclusive workplace for workers with disabilities.

PSi regularly hires the services of workers with disabilities in its packaging unit. To participate further in the collaborative economy, we will soon refit the company’s roofs to accommodate the hives of local beekeepers. To strengthen our relationship with our suppliers and to share our success, we plan to give back to producers by offering them finished products in proportion to their harvest sold to us.

This benefit will strengthen our ties to our suppliers and help them to appreciate their role in the product value chain. To combat counterfeit products, producers of Monoï de Tahiti joined forces to protect the traditional manufacture of monoï oil. In 1992, Monoï de Tahiti became the first cosmetic product to obtain the Appellation d’Origine (Appellation of Origin) label, currently the only such label in French Polynesia.

Promoting sustainable growth

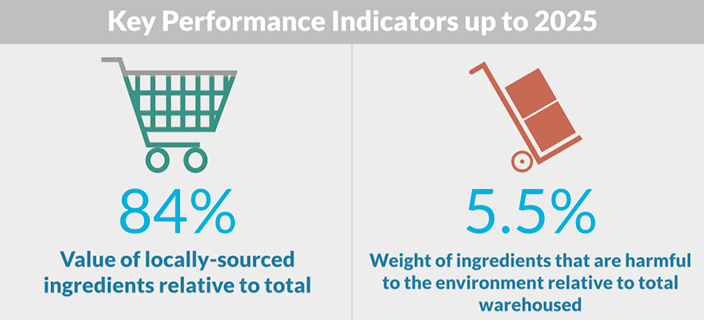

The goal of sustainable growth is to create a healthy environment, in which the community as a whole can thrive. Our suppliers of primary natural ingredients are located throughout French Polynesia. Seventy-seven percent of these suppliers live in the Tuamotu archipelago, on isolated islands such as Takume, Takapoto and Fakahina. Twenty-two percent live on the Society Islands, the majority of whom live on Tahiti, with 1% located on the Marquesas Islands and 1% on the Austral Islands. Through the purchases of coconut oil, tiaré Tahiti flowers and tamanu nuts, the share of sales transferred to Polynesian agriculture by LCPS in 2016 was 39%.To meet changing distribution needs, in 2013 PSi added a new production site in 2013 in Aubagne, in the South of France.

This was in response to new business, representing an investment of €2.5 million to purchase 2,300 sq. m. (nearly 25,000 sq. ft.) of property and the construction of a 1,600 sq. m. (nearly 17,000 sq. ft.) modern cosmetics production facility. For our business in French Polynesia, we prepared an investment package with the objective of expanding and modifying existing installations.

This expansion contributes to the company’s pursuit of innovation, quality and environmentally-friendly practices. It will also help to reduce the carbon footprint of the company and its products. New installations would also improve work conditions for our staff, reducing the strenuousness of certain work stations.